Computer chips are the building blocks of computers. They are designed to be small, fast, and efficient. The process to make computer chips is complex and requires a lot of specialized equipment and expertise.

This article will revolve around the topic “computer chips”, letting you know how they are made and what types of computer chips are there.

Table of Contents

- What is a Computer Chip, and How Does It Work?

- How Computer Chips are Made

- What are the 3 Most Common Materials Used for Computer Chips?

- What is a Nanometer and How is it Used in the Manufacturing Process of Computer Chips?

- What are the Different Types of Chips in the Market Today?

- Conclusion:

What is a Computer Chip, and How Does It Work?

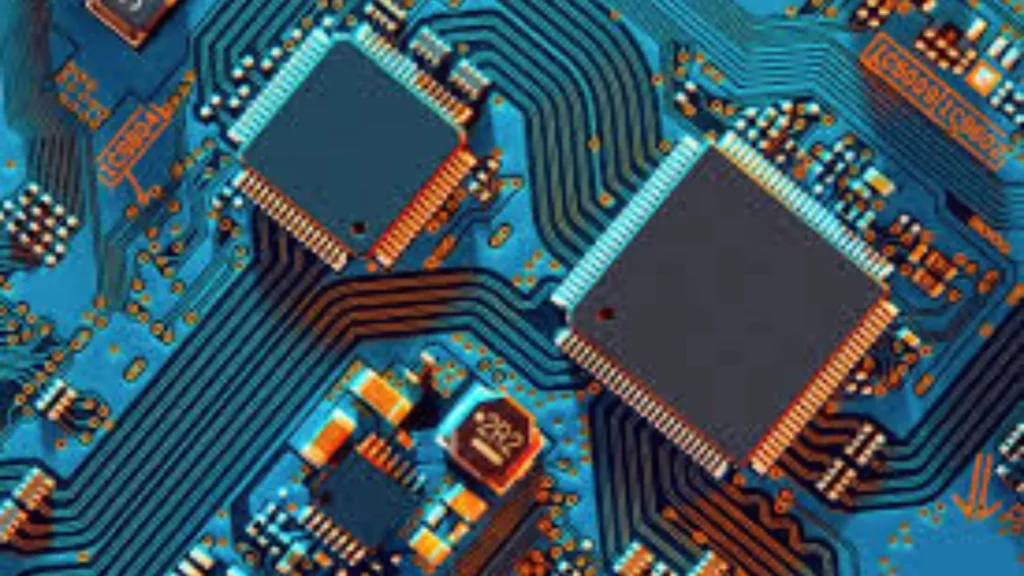

A computer chip is a piece of silicon that is used to perform calculations and store data.

Computer chips are the most important building blocks of modern electronic devices, such as computers, mobile phones, televisions, and cars.

A computer chip is composed of a large number of transistors that can be turned on and off in order to perform computations. These transistors are also known as switches because they can be turned on or off by an electric current. The switch is typically made from a semiconductor material that contains impurities called dopants, which are added to the silicon during manufacturing.

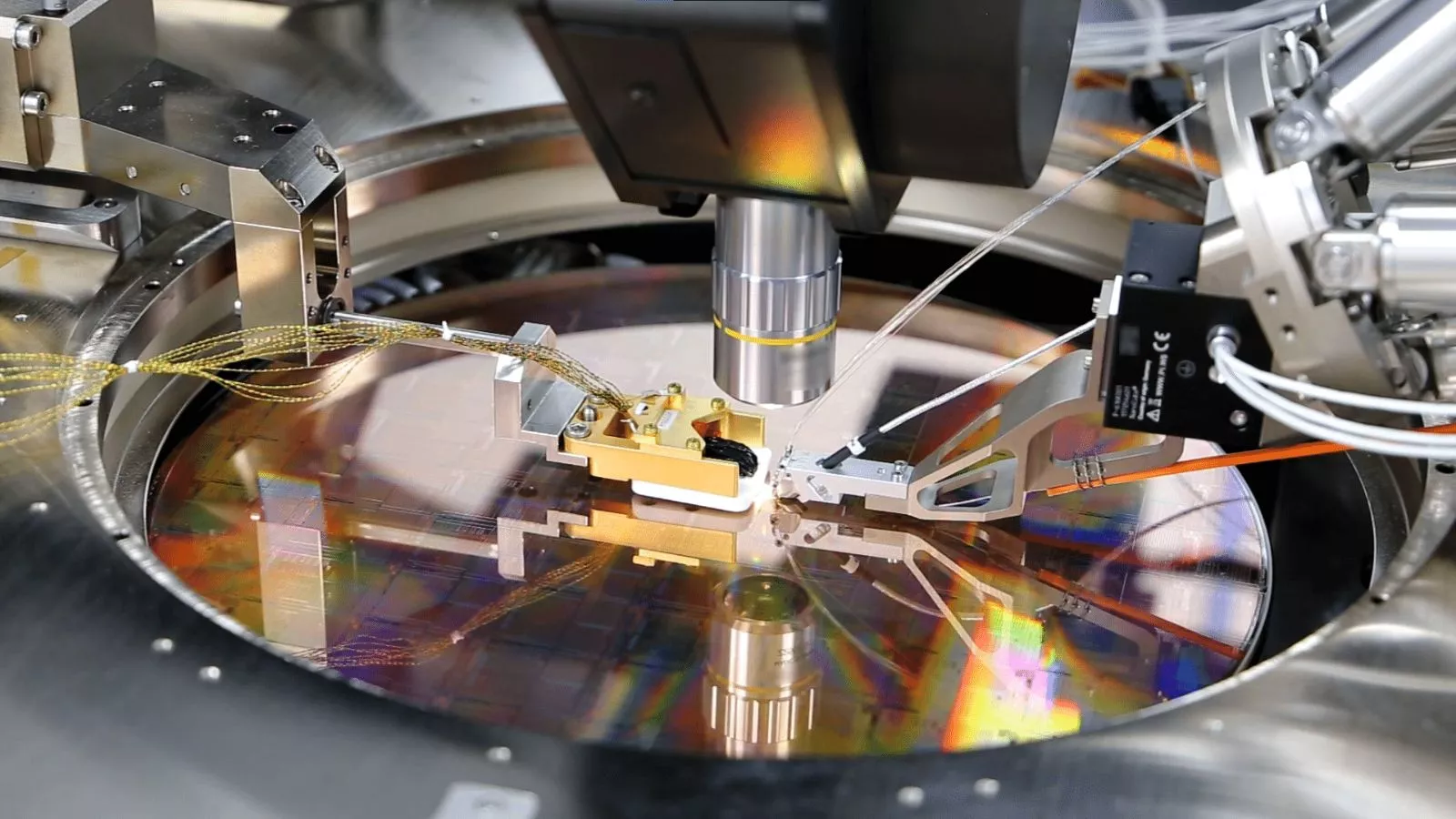

How Computer Chips are Made

The computer chip manufacturing process is a complex and time-consuming one. It can take up to several weeks for a single chip to be made.

Computer chips are made by first creating the circuit, then covering it with metal, and finally heating it to melt the metal into place. This process is also referred to as the CMOS manufacturing process.

Computer chips are manufactured in two steps:

1) Creating the circuit

The first step of the CMOS manufacturing process is creating the circuit. In this step, a metal layer is laid over a silicon wafer (the raw material).

The metal layer will become an electrical connection to other circuits on the board. The silicon wafer is cut into microscopic squares that are then coated with a thin layer of photoresist (an alkyd resin) that hardens when exposed to UV light.

Since the metal layer is an electrical connection, it must be connected to all other circuits on the board before it can be electrically active (the metal layer is selectively etched away).

2) Covering it with metal

In the second step, metal is applied over the board. This process begins when a solution of metal sulfide and hydrogen peroxide is painted onto the top of the square surfaces that have been coated with a thin layer of photoresist.

The metal sulfide forms a film on the surface and connects to any electrical connections on top of it by way will make a metal-to-metal connection.

The hydrogen peroxide oxidizes the metal sulfide to form a layer of metallic copper. Another way to describe how this process works is that the metal sulfide film on the surface of each square hardens when exposed to air, but oxidizes when exposed to hydrogen peroxide so that it can make contact with other surfaces on the board.

What are the 3 Most Common Materials Used for Computer Chips?

Computer chips are made of different materials depending on the function they are designed to perform. For example, a computer chip that needs to be fast and efficient would need a material that is light, conductive, and can withstand high temperatures.

The three most common materials used for computer chips are:

- silicon

- gold

- Fraxel

These materials are used because they are light, conductive, and can withstand high temperatures. Some computer chips also use other materials, like tungsten carbide to make the chip more durable and increase its lifespan.

What is a Nanometer and How is it Used in the Manufacturing Process of Computer Chips?

Nanotechnology is the application of nanometer-scale engineering and technology. Nanometers are a billionth of a meter, which is the length of an atom or molecule. The process that uses nanotechnology is called nanofabrication.

Nanotechnology has been used in the manufacturing process of computer chips to create smaller and more efficient devices. This has led to faster processing speeds and increased battery life for mobile devices.

What are the Different Types of Chips in the Market Today?

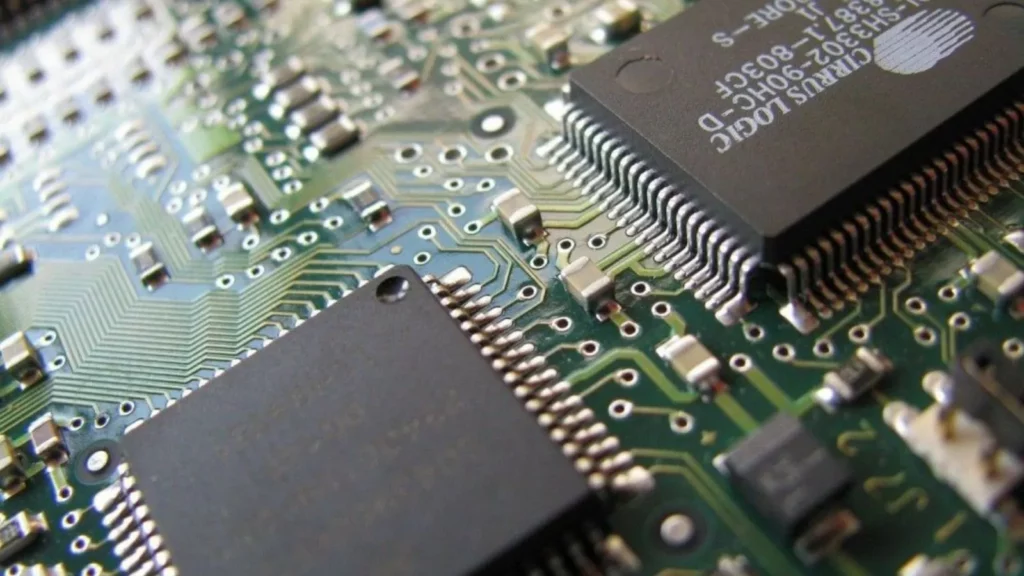

Computer chips are the most important components of a computer. It is a semiconductor device that converts electrical power into digital signals and vice versa. There are many types of computer chips in the market today.

The most popular ones are:

- Microprocessors = For general-purpose computing

- Central Processing Unit (CPU) = For servers and workstations

- Graphics Processing Unit (GPU) = For gaming computers

- Field Programmable Gate Array (FPGA) = For embedded systems

- Digital Signal Processors = For high-end audio/visual equipment

- System on Chip (SoC) = For smartphones, tablets, and other handheld devices.

Conclusion:

In this article, we have explored how computer chips are made, how do they work, what materials are they made of, and what different types of chips are available in the market today.

All these things conclude that:

The process of making computer chips is a lot more complicated than it used to be. It involves a lot of hands-on work and the need for experts in many different fields.

Computer chips are the most important part of any electronic device, so they need to be made with care and precision.